Table of Contents

Intoduction’s Micro Concrete Flooring

Present-day, consistent, and ultra-sleek—micro concrete flooring has rapidly become a favorite among creators and property holders alike. With its capacity to change existing surfaces into high-end, strong wraps up, miniaturized scale concrete (frequently alluded to as microcement flooring or microtopping) offers a common and a la mode elective to conventional flooring solutions.

In this directory, we’ll walk you through everything you require to know, from what small-scale concrete really is to its benefits, applications, establishment preparation, and how to discover micro cement flooring close to you.

What Is Small-Scale Concrete Flooring?

Micro Concrete Flooring—also known as miniaturized scale cement or microtopping—is a polymer-modified cement-based coating connected in lean layers over existing floors, dividers, and other surfaces. With a thickness of as it were 2–4mm, it makes a hardwearing and enriching wrap-up that takes after cleaned concrete but without the bulk or weight.

Unlike conventional concrete, which needs more profound pours and overwhelming arrangement, small-scale cement floors can be connected straightforwardly over tiles, screed, concrete, wood, and indeed drywall.

Why Select Microcement Flooring?

Consistent and Smooth Look

Micro Concrete Flooring gives a joint-free wrap-up, advertising a clean, cutting-edge edge that complements modern add. It’s perfect for open-plan homes, extravagant lofts, cafes, and showrooms.

Tall Durability

Microtopping is not a fair aesthetic—it’s built to final. Once fixed, it’s safe for foot activity, water, UV beams, and indeed chemical exposure.

Appropriate to Numerous Surfaces

It’s not fair for floors. Small-scale cement can be connected to:

- Interior and outside floors

- Bathroom walls

- Kitchen Countertops

- Staircases

- Furniture

Consistent with Underfloor Heating

Because it’s so lean, micro cement flooring works superbly with brilliant warming frameworks, making it a cozy and energy-efficient flooring arrangement.

Different Types of Micro Cement and Microtopping Finishes

Micro Concrete Flooring frameworks come in different wraps, permitting for full customization depending on your plan goals:

- Smooth matte miniaturized scale cement floor for minimalists

- Polished concrete impact for extravagance interiors

- Textured or troweled wraps up for a mechanical or rural vibe

- Pigmented alternatives include profundity and personality

Common Applications of Microcement Flooring

Private Spaces

- Living rooms and hallways

- Kitchen and lavatory floors

- Feature walls

- Furniture like seats and tables

Commercial Environments

- Retail shops

- Hair salons and spas

- Hospitality venues

- Office floors

Open air Use

With the right sealant, miniaturized scale concrete is UV- and weather-resistant—ideal for patios, walkways, and plant highlights.

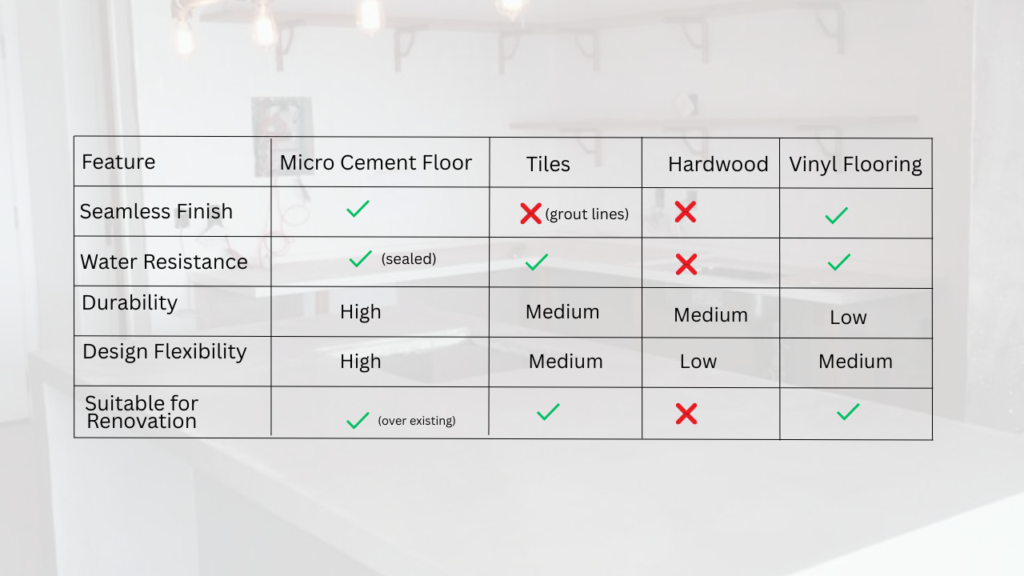

Micro Cement vs Other Flooring Options

The Installation Process

Installing a small-scale cement floor includes a few key stages and regularly takes 3 to 5 days:

- Surface Preparation

Existing floors are cleaned, repaired, and prepared. The surface must be dry, steady, and level.

- Application of Base Layer

A base coat of miniaturized scale concrete is troweled on. This is the foundational layer for holding and strength.

- Wrapping up Layer

A moment layer is included to accomplish the craved surface and color.

- Sanding and Sealing

The surface is sanded, at that point fixed with a defensive coating for water and recolor resistance.

Note: Whereas DIY units exist, it’s unequivocally exhorted to contract a proficient for best results—especially if you’re looking for Micro Concrete Flooring close me with demonstrated encounter and quality.

Where to Purchase Small-Scale Cement?

You can buy miniaturized scale concrete frameworks from:

- Specialist flooring suppliers

- Decorative concrete companies

- Online stores advertising micro cement kits

- Local temporary workers (a few incorporate fabric costs in their packages)

When looking where to purchase small-scale cement, make beyond any doubt the item incorporates a full framework: groundwork, base, micro cement, and sealer.

Maintenance and Care

Daily Cleaning

- Sweep or vacuum routinely to avoid soil buildup.

- Use a pH-neutral cleaner when mopping.

Long-Term Maintenance

- Reseal the floor each 3–5 a long time depending on foot traffic.

- Avoid dragging sharp or overwhelming objects that can scratch the seal.

One of the best reasons individuals select microtopping is its low-maintenance nature, making it perfect for active family units and commercial situations alike.

How to Find Microcement Flooring Close to Me

Looking for a trusted installer or provider? Utilize look terms like:

- Micro Concrete Flooring close to me

- Micro Concrete Flooring floor installation

- Where to purchase miniaturized scale cement locally

You can also check online marketplaces or registries, or get proposals from neighborhood builders and designers.

Tip: Continuously check surveys, past ventures, and item determinations sometime recently choosing a provider or contractor.

Conclusion: Is Small-scale Cement Flooring Right for You?

If you’re looking for a flooring arrangement that’s modern, customizable, and tough, a small-scale cement floor seems to be the idealize fit. Whether you’re planning a smooth present-day domestic, remodeling a commercial space, or fair tired of grout lines and chipped tiles, microcement flooring offers magnificence and flexibility in rise to measure.

From lavatory dividers to living room floors, microtopping can lift your space while keeping it simple to keep up. Fair keep in mind: choosing the right installer and quality materials is key to getting the long-lasting wrap-up you’re after.

FAQs About Microcement Flooring

Is microcement slippery?

It can be, but anti-slip sealers or additives can be applied for added safety.

Can it be used in bathrooms and wet areas?

Absolutely. With proper sealing, it’s 100% water-resistant.

How long does it last?

A well-installed micro cement floor can last 10–15 years or longer with regular care.

Is it expensive?

Costs vary from £80 to £150 per square meter, depending on the size, surface condition, finish, and whether you’re hiring a local installer or buying DIY kits.